GeoBot-1

First

Outdoor Autonomous Testing

Updated 12/18/05

GeoBot-1

First

Outdoor Autonomous Testing

Updated 12/18/05

|

After what seemed like forever, we finally

finished our new bumper design for the GeoBot. Many different

prototypes were tried, however it was the dual plunger design

that was able to take a beating on hard rock hits and yet provide

a delicate sense when traversing heavily weeded areas. For this

series of tests, we took the robot to an area with rocks ranging

in size from pea gravel to football sized boulders. The results

indicate that the instrumented front bumper does an admirable

job at keeping the robot from getting into trouble from large

obstacles encountered in a real world situation. When the sonar

is added, the bumper will be the fall back system in case the

sonar does not detect an object. Here are the details.

Don't forget to

view the MPG movie at the end, you can see Geobot in action!

|

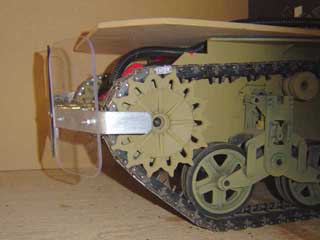

Click on the thumbnails for a 2x larger view  | The

dual tread system has just enough tension to drive reliably,

yet can conform to large rocks and branches. |

| You

can get a feel for the extreme terrain we put this robot through.

The bumper height is set such that if it cannot climb over a

rock the bumper will be triggered and the robot goes into an

escape maneuver to drive around the rock. Later, sonar will take

over this task. |  |

| Because

the tread conformed to the rock surface, good traction was maintained

in such difficult conditions. It became apparent that an inclinometer

would be a good addition later, in that we don't want to tip

over or try to go up too steep of an incline. |

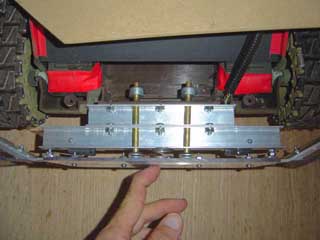

| Now

for some details on the bumper. Its best to remember that you

build the bumper first - THEN instrument it with switches. This

way you don't get into the mind set of the switches dictating

the bumpers design, which is usually doomed to failure. Here

you can see the 1/8 aluminum bar with the lexan plates mounted

on it to increase the coverage. The bumper sits 2 inches below

and 3 inches above. Anything below the bottom of the bumper can

be driven over for the most part. |  |

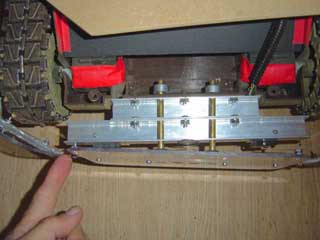

| Front

view showing the three lexan panels mounted on the aluminum frame. |

| The

ground clearance of the Geobot is very good, well over 4 inches.

The bumper plates are in front of the treads and in the middle. |  |

| How

the bumper works, some details. A weak spring pushes the bumper

bar outward and it is attached to the two brass rods. These slide

in and out of the U channel forming a slide. However, one difference

- the attachment point of the rods to the front bumper is flexible,

made from rubber encased steel washers at the joint. Pushing

in the center, pushes both rods in and closes both switches. |

| Pushing

on one side makes the rods move inward differentially, and closes

the left side switch only. This type of bumper arrangement, which

can be described as a dual spring loaded plunger type is very

robust, and can take an extreme beating without harm. There are

limit screws on the bumper to keep the bumper compression limited

as to not crush the lever switches. |  |

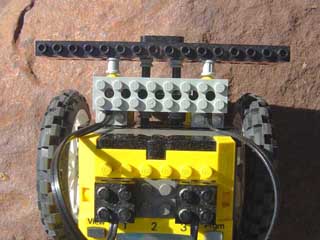

| The

final prototype for our dual plunger design was developed over

several months using Lego technology. This prototype design is

in a dual skid drive robot we eventually named "SkidBot"

because of its weird turning action. You can see more on this

robot Here. |

1.5Mb mpg Video

1.5Mb mpg Video

| finally,

a small movie clip with sound showing a 75 foot excursion through

some very rough rocks and weeds to show how it works without

any sonar yet. Unfortunately, and airplane was flying over during

the run! |

HOME

HOME

You are visitor

number since June 17, 2001

FastCounter

by bCentral

HOME