Updated 1/9/05

Updated 1/9/05

P.A.A.M.I's

Docking Station and Charging Contacts

|

Last time we discussed the electrical schematics

and circuitry for

building a battery charger for your robot. In this part two of

a series of three articles on self charging robots, we illustrate

our method of making contact with the charger, and a docking

station for your robot to dock with and charge its batteries

when needed.

Contact types

There are three basic ways

to connect your robot to a charger, first the robot basically

plugs itself in to a standard connector arrangement, and second

a frictional contact array or spring loaded separate contacts.

A third method, which is seldom used is to use charging coils

in a base and robot to inductively connect the robot to the charger.

While the first method seems to be the obvious choice, the accuracy

required to plug two connectors together makes it a difficult

task. The third method involves large and heavy inductive coils

and is generally less suitable for home robots. We therefore

found that the second method is the best for around the home

and is easy to make.

Contact plates

This method works with

a wide range of misalignment , and is simple to construct. We

tried spring loaded copper contacts, assorted guitar springs,

pressure plates, contact fingers, carbon brushes, and even rolling

metal wheels with metal axles. Each has its merit, but none was

more successful and reliable for us than the copper plate and

spring ball method. The idea is to have either the robot or base

have a two plate flat copper or brass board, in which the spring

loaded balls slide onto. The problem with putting a copper plate

on the front of a robot such as is used in the Octobot, is that

that valuable real estate on the front is taken up, where we

would normally put IR sensors and bumpers. The same would be

true with spring loaded contacts on the front of the bot. The

answer then is to put the copper plate on the BOTTOM of the robot,

and have it slide over the spring loaded balls. That way your

not dragging the contacts around the house on the robot, picking

up socks, and cat toys on the connections.

But does it work?

Using this arrangement,

we have had 95 percent success on the first attempt when docking,

and 100 percent on the second pass. When the robot fails to connect

for some reason, it simple backs up and goes forward again and

gets it on the second try. Our next article will detail the programming

for docking, charging and escaping the charger in more detail.

Now on to the hardware photos and descriptions!

|

| The docking

/ feeding station. The T shaped base contains the contacts and

is stable with a three point support. Above it is the metal electronics

box, containing the beacon array, 18vdc 1.6A power supply used

by the robots charger, and the bumper to prevent impact with

the clear beacon dome. On the top is a 20 pound steel weight

to keep the charger in place. (Almost looks like a counterweight

for a telescope, doesn't it?) The beacon sends a beam with 5

high power IR LEDs that is modulated at 38.5 kHz. The beam width

is narrower than the docking acceptance angle for the robot -

this is critical to insure a successful docking. |

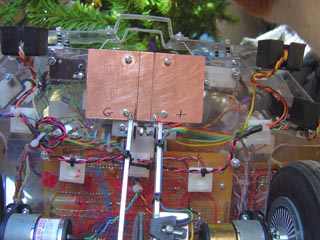

| Contact arrangement.

Two brass balls from the hardware store used in lamp shades were

drilled out (they are tapped for #8) to press fit onto the expansion

springs. These are the type that are all squeezed shut and you

pull on them to expand them like a rubber band. They sit about

1/8 inch above the bottom of the robot and will drag across the

copper plates underneath the bot. |  |

| Side view.

To connect the wires to the springs, we soldered the wires first

to brass shim stock, and wrapped it around the base of the spring.

Then a tie wrap secures it to the spring. The springs can be

bent over 90 degrees and be even run over by the robot with out

any problem of springing back. And believe me, your robot WILL

run over them from time to time! |

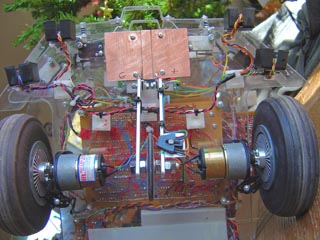

| The underside

of PAAMI shows the copper plate on the front for contact electrically.

The left side is ground, and the right side is for the +18vdc.

Note the barrier between them that has no connection for safety.

The balls obviously must not contact both and short them so that

why the barrier was put in. The width is about 3 inches and depth

about 2 inches - plenty of "runway" for the balls and

to stop the rolling robot in time. |  |

| Close up

of the plates. I used 4-40 pan heads to secure it to the lexan,

and the balls just bounce off them when these hit. |

| Looking at

the front of the robot, just underneath to show the copper plates

are flush with the bottom lexan. Of course the drive motors and

stasis sensor wheel hang below too. |  |

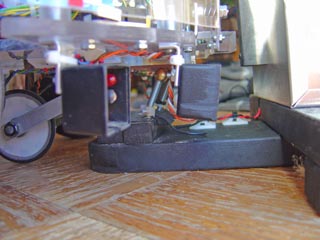

| Not an easy

shot to take, You can see the balls on the springs leaning forward

as they contact the underside of the robots copper plates. The

black boxes contain the IR proximity sensors (IS417 type) |

| PAAMI cruising

along in an area of the kitchen where the robot seems to visit

most frequently. The charger is just in the sun. IF she is hungry

(low battery) AND the beacon sensor sees the beacon THEN the

charge level in the 8 layer priority arbitration architecture

kicks in and causes the docking behavior. |  |

| First, she

rotates toward the beacon using the beacon sensor. By rotating

rather than banking the turn, we don't have to worry about hitting

anything and therefore the charge processor subsumption level

does not have to look at the IR prox or bumpers. |

| Heading directly

toward the charger. It may make a correction or two in direction

along the way, but it generally heads right for the beacon within

about an inch accuracy. |  |

| Looking over

the top of the bot as it heads directly for the beacon in the

dome on the feeding station. The beacon sensor is also in a dome on the top of the robot to protect

it from the evil coffee table shelf. It has a guitar string bumper

in front of it as well. T'Pring watches as the robot nears the

charger. |

| DOCKED! The robot sees the voltage

on its copper plates, then stops, shuts down everything except

the charge processor and soaks up the energy. Takes bout an hour,

then it turns systems back on, backs up and does a charger escape

maneuver to clear the charger. Although the beacon sensor will

see the charger many times in the hour or so It runs, it will

simply ignore it until it has a low battery. Ahh, the wonders

of Priority Arbitration Architecture ! |  |

MPG move Clips with sound of the robot in action docking.

Still from actual Movie

Still from actual Movie

| 385

Kb - for standard modem connections. In these movies, taken with

my Sony P10 digital camera, the sound reveals the robots response

to the charger. First, you hear the "Pip.....Pip" of

the sonar of the level 0 subsumption level scanning the area

ahead for obstacles. The when the robot sees the charger, it

makes the "Happy Sound" and homes in on it. |

Still from actual Movie - half sized

Still from actual Movie - half sized

| 5.3

Mb - for high bandwidth connections. You'll like this one. |

Still from actual Movie - half sized Still from actual Movie - half sized | 6.9 Mb -

for high bandwidth connections. Shows the bot hunting for the

beacon on the way in. |

HOME

HOME

You are visitor

number since June 17, 2001

FastCounter

by bCentral

Still from actual Movie - half sized

Still from actual Movie - half sized

HOME