Cbot

- Plant Maintainence Robot 1

Preliminary

Development Projects

Updated

4/25/15

Key

Search Words: ROBOT, ROBOTICS, ROBOTIC VISION, ARTIFICIAL INTELLIGENCE,

AI

Cbot

- Plant Maintainence Robot 1

Preliminary

Development Projects

Updated

4/25/15

Key

Search Words: ROBOT, ROBOTICS, ROBOTIC VISION, ARTIFICIAL INTELLIGENCE,

AI

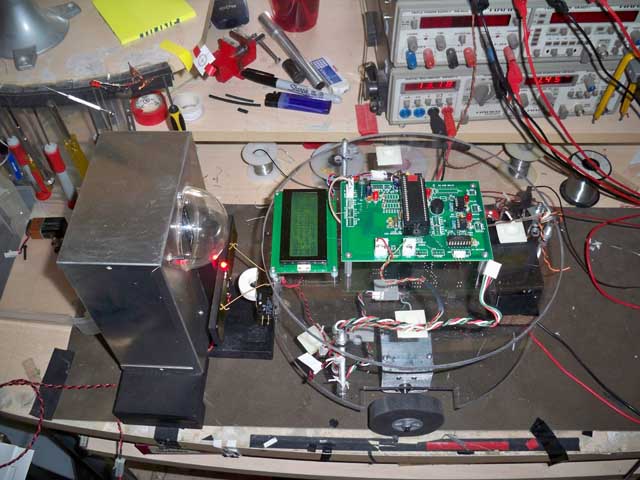

| Here

is an update on the current progress of the Cbot Robot. For the

second half of April, I concentrated on developing the automatic

battery charger and beacon so that we can keep the robot at full

power during the next phase of testing. One of the most important

functions a household robot must do is be able to find the battery

charger, plug itself in, and charge itself up on a daily basis.

For the Plant robot - this means that after it has completed

its watering task every morning, it must return to the charger

and slowly top off the 12v battery for the rest of the day and

into the night. The next morning the Sun comes up - and we do

it all over again. Below you'll find some photos of where we

are at on this and an inside look at how the brains of the robot

will accomplish the entire watering task! |

| Left: First

thing was to construct a solid and reliable docking station,

complete with 500 ma battery charger, an adjustable infra red

beacon and two charging plates the robot can drive into to connect

up. Here is a bench test of this in action. The docking station

is on the left and has a red light just above the contacts to

confirm there is voltage present. (13.5v to charge a Gel Cell).

The robot on the right (without its dome) has two "feelers"

made from a Guitar E string that are connecting to the plates.

The battery is able to charge fine WHILE THE ROBOT IS ON. This

allows the robot to just drive up and charge at will. |

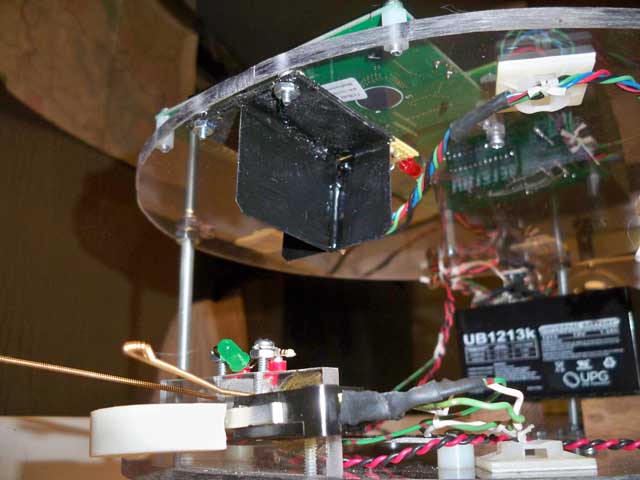

| Here inside

the robot arena, you can see the charger/docking station more

clearly. The electronics are inside the metal box, and the dome

at top has a bar of infrared LED lamps for the robot to home

in on to park itself right on the plates. |

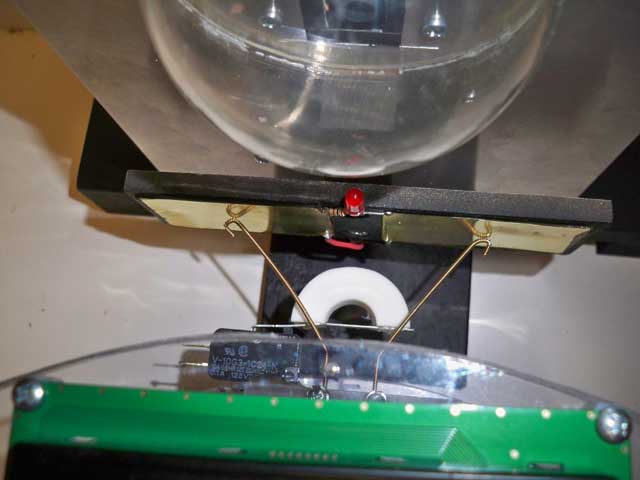

| Viewed

from above, the guitar strings are just touching the plates and

connect directly to the battery terminals in the robot. The white

C shaped foam piece is connected to a lever switch. If the robot

keeps driving towards the plates and does not stop because it

detects no voltage, the switch closes and that will stop the

robot. It is a fail safe. |

| Inside

the docking beacon. The bottom board is a small 12F629 micro

controller that puts out a constant 38.5 khz signal. This drives

the second board which contains the IR LEDs. |

|

Click to

enlarge!

| The

docking beacon detector that is to be installed on the front

of the robot started out like this, three pieces of brass shim

stock soldered to form a vane sensor. Two photo cells that respond

to 38.5 kHz Infrared light are on each side of the vane. by pointing

the vane right at the beacon, both photocells will put out a

signal. If its to the right or left - only one will thus the

robot can home in on the beacon. This all gets painted flat black. |

| The

beacon sensor now installed on the underside of the top plate

of the robot. |

|

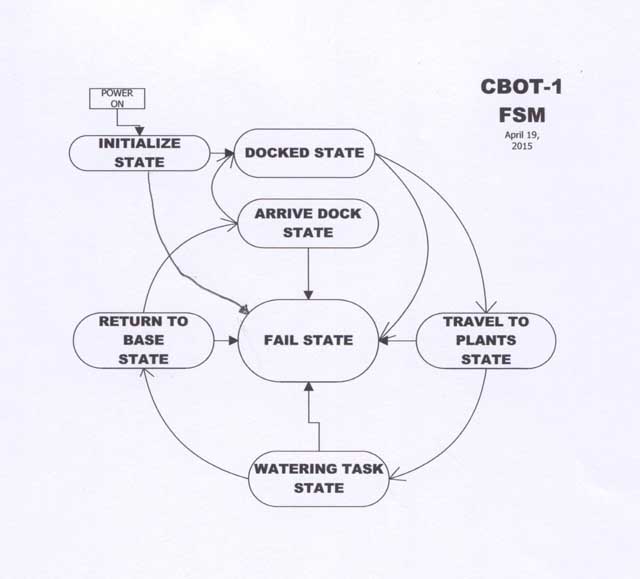

A diagram to show

how the robot is currently being programmed to accomplish the

plant watering task. This type of diagram is called a "Finite

State Machine". Each bubble is a separate state the robot

can be in at any time, depending on what its doing. Each state

is simply a separate block of code. The arrows show how it can

jump from one state to another.

The human brain

works in a similar manner. We mentally jump from one mind set

to another all the time, say from walking to driving a car then

talking on the phone. Each task we do is a separate mind state.

Same here. This technique is very powerful in defining the artificial

intelligence of microprocessor controlled systems.

|

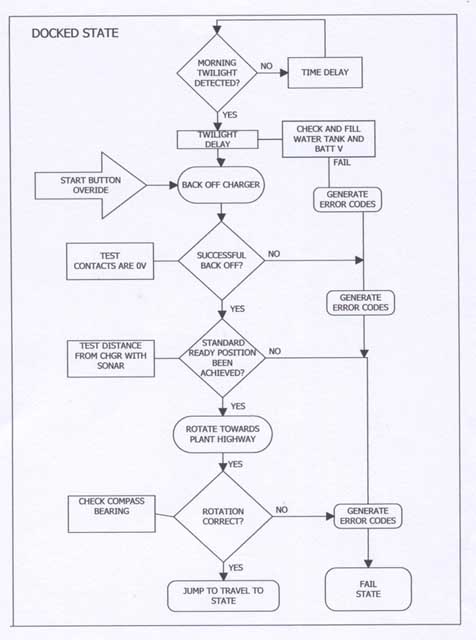

| Here is

an example of whats inside each bubble above. This is for example

the "Docked State" internal flow chart. Each bubble

has its own internal diagram like this and you use it to guide

you as you actually write the program to put into the robots

micro processor. I have not finished ALL of the inner flow charts

yet, but each step of the way is clearly defined for the future! |

BACK TO ROBOT PAGES

HOME

HOME

HOME