|

We next advance upwards to this next level

of visual complexity by using a scanning method for image production

reminiscent of the old NASA Viking landers. These Mars landers

used a mirror to scan the scene in both a horizontal and vertical

format to generate a full 2 dimensional image that was digitized

and sent to Earth back in the mid 70's. For our new project,

we will be evolving our visual method to the level of the first

most primitive animals on Earth that could form crude images

of their surroundings for an advantage in survival and feeding.

Let me explain this in more detail. Small slug like animals which

were amongst the most advanced creatures to exist at their time

some 600 million years ago in the seas were able to at best use

two eye spots that did not form images to get information on

their environments. That was the focus of the last project, the

Rotifer program. As the requirements for vision increased, and

the first hard shelled animals appeared, a much more complex

mosaic type of vision evolved. Here, the eye spots started splitting

into groups, and formed clear lenses over them to enhance their

light sensitivity in dark sea bottom environments. The Trilobites

were the very first animals that could form images - however

crude - of the Earth, and for the very first time, a living

organism could actually see the world!

The "Trilobite"

project as this is called re-creates that first moment of animal

vision, and explores how it might have been used to enhance the

small creatures existence. Then, we can extend this knowledge

to Robotic vision and how it might move us into a new realm in

the house hold navigation capability.

Click above Thumbnail for a larger view

Click above Thumbnail for a larger view

|

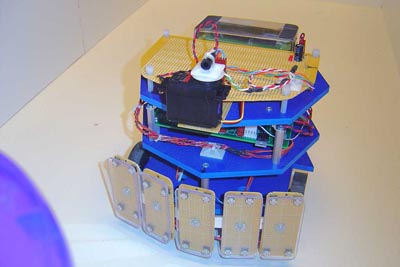

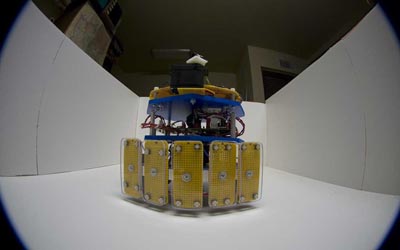

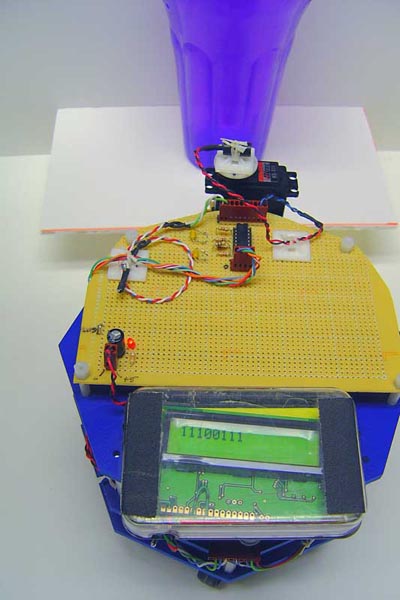

This

new version of the Vision Logic Robot shows the servo motorized

scanning platform on the front top of the main deck. Even though

the slow scanning process makes for processor sharing headaches,

I found that the flexibility of being able to change the pixel

resolution with a simple code change was enticing enough to demonstrate

the concept. For this initial run, we don't move the robot yet,

it is simply scanning the surroundings for brightness variations

and producing an interpretation on the LCD display. The scanning

angle is 180 degrees from left to right and takes about half

a second each direction. |

Click above Thumbnail for a larger view

Click above Thumbnail for a larger view

|

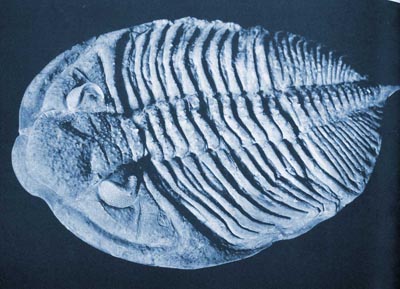

This

is a full body view of an ancient 400 million year old trilobite

fossil. The eyes are on the left side, and are seen as two arcs

that form a backing for the eye facets. The angle of vision is

astounding, a full 360 degrees of visual range is seen here -

however you must remember this is in a very narrow plane that

essentially looks straight forward, and a backwards over the

back of the animal. It cannot see down, up or upward at any angle.

Despite this limitation, trilobites were amongst the most successful

animals ever on earth and lasted hundreds of millions of years

before going extinct. |

Click above Thumbnail

for a larger view

Click above Thumbnail

for a larger view

|

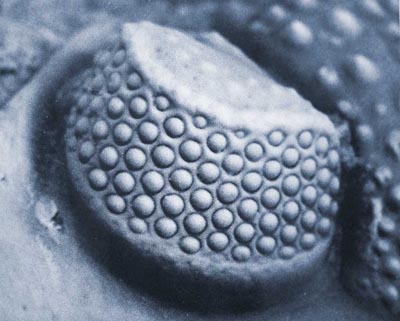

A

close up of a trilobite eye which shows the individual eye lenses.

Each lens focuses light onto a small patch of retinal photo sensors,

but no image is formed. Each eye acts a single very sensitive

photocell, and the resolution is very crude on the surroundings

of the animal. Later in the evolution of the trilobites, the

resolution increased 10 times or more and less crude images were

impressed on to the primitive brain of the animal. The animals

amazing success is no doubt due in part to the invention of a

mosaic type vision of the animals surroundings. |

Click above Thumbnail for

a larger view

Click above Thumbnail for

a larger view

|

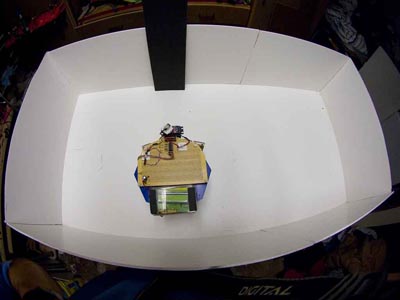

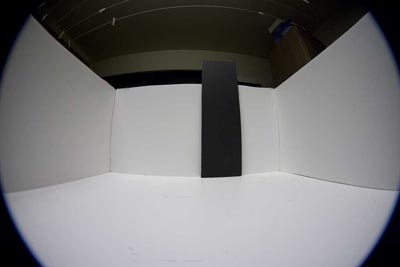

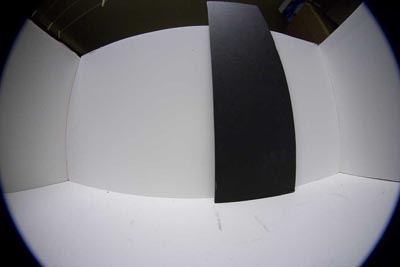

The

Vision Logic Robot (VLR) in the test arena. The walls out of

white foam board have been extended upward to give the vision

system under test a controlled plain background for basic vision

performance characterization to be made. Objects such as this

black piece of foam board can be placed into the arena, and the

robots response noted. |

Click above Thumbnail for a larger view

Click above Thumbnail for a larger view

|

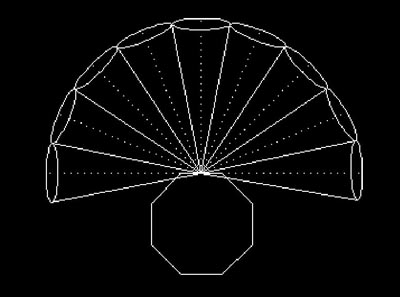

The

motorized vision scanner produces 9 pixel resolution, each non

overlapping field is 22.5 degrees wide and encompasses a range

of 180 degrees of field. The scan starts on the left and moves

right, at 22.5 degree increments stopping only for a few tens

of milliseconds at each position to take an analog reading from

the photo transistor. This is buffered with a rail to rail Op

amp, and sent to the analog input of the processor. |

Click above Thumbnail

for a larger view

Click above Thumbnail

for a larger view

|

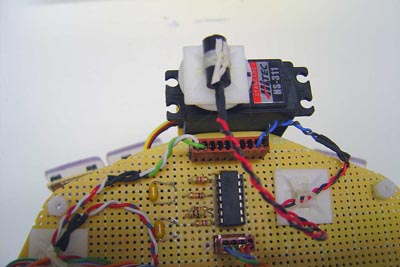

Implementation

of the scanner was fairly straightforward, a standard hobby servo

motor had the photocell assembly secured on top and could be

slewed quickly to the next position. The photocell amplifiers

are on the circuit board and consist of a very nice rail to rail

single supply op amp, the quad package TS954 from Texas Instruments. |

Movie 1

|

A

short mpg movie of the scanner in action showing the right-left

then left-right scan. |

Click above Thumbnail

for a larger view

Click above Thumbnail

for a larger view

|

In

an experiment, the robot is manually placed various distances

and angles from the target, seen here as a medium colored cup. |

Click above Thumbnail for a larger view

Click above Thumbnail for a larger view

|

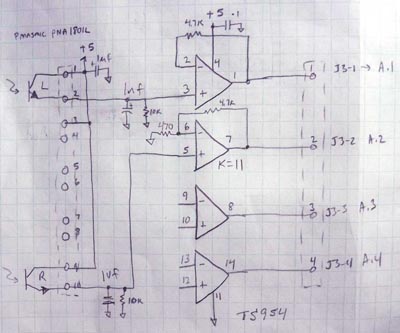

Schematic

of the photocell amplifier. I'm only using one photo detector

for this experiment. The RC filter keeps out the 120hz ripple

from the overhead fluorescent lamp from slamming the amplifiers. |

Click above Thumbnail for a larger view

Click above Thumbnail for a larger view

|

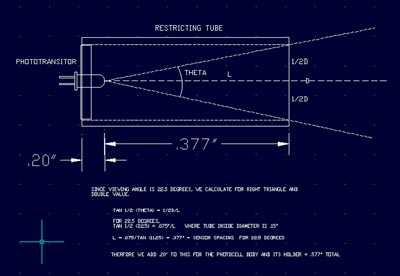

Restrictor

tube calculations. To limit the field of view of the photodetector

to the required 22.5 degrees or any other for that matter, you

use simple trigonometry to calculate the length of the black

restrictor tube. |

Click above Thumbnail

for a larger view

Click above Thumbnail

for a larger view

|

A

180 degree fish eye lens view of what the robot will see at 2

feet from the 5 inch wide target. Notice how small it appears

in the field even that close. This is what the robot will see

as well. |

Click above Thumbnail

for a larger view

Click above Thumbnail

for a larger view

|

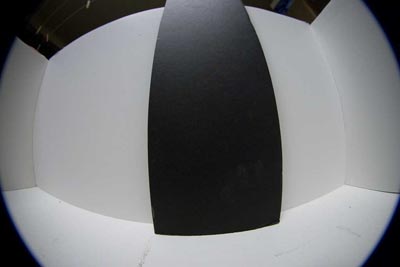

From

the target looking back at the robot in the arena. The scanner

is ready for testing. |

Click above Thumbnail

for a larger view

Click above Thumbnail

for a larger view

|

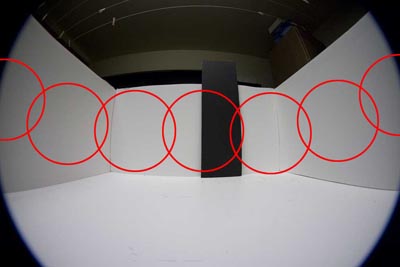

When

the robot scans the field in its one dimensional view narrow

horizontally like our primitive trilobite, its 22.5 degree fields

are super imposed as seen here on the distant target. This target

could be in the real world a cave, tree trunk or anything dark

that might provide information to the animal, or in this case

the robot. |

Click above Thumbnail

for a larger view

Click above Thumbnail

for a larger view

|

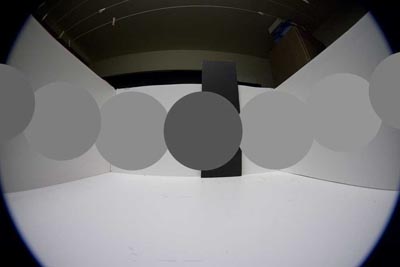

As

the photocell reads each circle it puts out an average of the

brightness in each field integrated over the entire 22.5 degree

circle. Note that at this very poor resolution, the totally black

target gets averaged in with its white surroundings, and comes

out as a medium gray. This is what the robot will have to interpret

as its visual scene. |

|

The

above image scan produces a 9 pixel image of a strip extending

180 degrees around the front of the robot. See how the black

target is hardly visible compared to the shadings on the walls

of the enclosure. At this resolution, the robot would not be

able to find the target since it looks just like the walls shadings. |

Click above Thumbnail

for a larger view

Click above Thumbnail

for a larger view

|

Moving

six inches away from the target makes it take up much more of

the scene. Again, this is what the robot has to see - a full

180 degree field from its left side on the left to its right

side on the right. (Aren't fish eye lenses fun!) |

|

Now

we can see the dark target! Again, as the circular fields cover

the edges of the target, we get a medium gray shade on each side

of the black target. Think of this as a rather blurry view of

the world. |

|

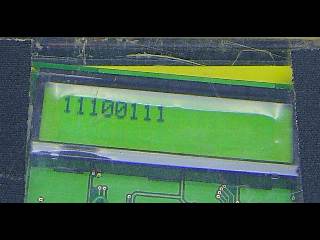

In

this case the above data was converted to a 1 or 0 binary value

pattern for analysis. Remember, robots see the world as 1's and

0's and have to convert this greyscale data to binary to view. |

|

There

are many more sophisticated methods to analyze the gray scale

values in an image as well, but I'm going to keep it simple right

now and see what can be done on the crudest levels. To create

this binary view, the data is scanned by the robots processor

and a maximum and minimum value is extracted. A threshold slice

point is calculated from this range, and used to covert the greyscale

image into a usable data format for processing. the formulas

for this conversion are:

threshold = (Max

- Min)/3 + Min

This gives a very

solid binary representation of the image.

|

Click above Thumbnail

for a larger view

Click above Thumbnail

for a larger view

|

At

a distance of a few inches, the target becomes quite dominant.

This is how close I had to have the purple cup to see it at all.

The contrast is key here. The bottom line is - Low resolution

vision means short detection range. This is why there was a push

in evolution for increasingly higher visual acuity and more pixels! |

|

Greyscale

data for above scan |

|

Thresholded

data for the processor. A very strong detection indeed. |

Click above Thumbnail

for a larger view

Click above Thumbnail

for a larger view

|

Live

display image from a test run, the above image was represented

as 0 for below threshold, and 1 for above. For the nine positions

measured, you can see the walls read 1's, and the black target

reads 0's. With this visual data available, the robot could for

instance determine the distance and position of a known obstacle

and the direction it had to go to avoid it. |

Click above Thumbnail

for a larger view

Click above Thumbnail

for a larger view

|

For the purple

cup, point blank or up to maybe six inches was the detection

limit (look at the display in the enlarged image), since the

contrast was much lower. The real world is obviously not all

black and white, and when we get higher visual resolution in

future projects, we can see the purple cup further away. For

now, the robotics applications can be understood clearly. Black

and white targets can be placed in the home environment and used

as beacons to guide the robot to its destination. It can also

mark with a unique pattern directions to go and a rough range

can be calculated based on object contrast.

In our next step,

the robot will be moving, and talking. I will demonstrate visual

navigation basics with such crude vision, and object avoidance

and identification. The final point here is that compared to

a blind bumper endowed home robot, a new level of environmental

awareness can be made available to the device, and is entirely

passive - no laser beams or IR transmitters required!

|

|