|

Introduction:

|

This

new robot is a second round on the engineering of a simplified

floor cleaning drone, the first was Vacbot completed a few years

back. Unlike that robot, which was built from a modified commercial

floor sweeper, SweepBot is completely custom built from the ground

up. The task of this new robot is simple: Perform a daily short

period clean sweep of the bathroom tile floor, to keep litter

that has escaped from the cats litter box at bay. The robot must

be autonomous, with little maintenance other than an occasional

emptying the dust bin from an operator. |

Mode of Operation:

The robot consists

of two separate sections, the “Carrier Robot” and the

“Mechanical Sweeper” assemblies. By separating the

two this allows simplified sweep section maintenance, or replacement

if needed. The sweeper section is nested inside the carrier,

and floats on the tile surface held up by a spring suspension.

The carrier and sweeper each have their own rechargeable batteries

connected to one charging board.

The Carrier Robot:

|

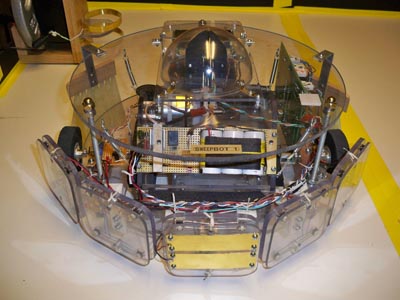

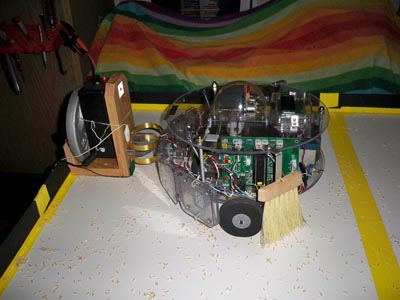

The

Sweepbot carrier robot is almost completely finished. Here, the

robot is connected to its IR Beacon/Battery Charger hoops which

was developed in the PICbot series of projects. The robot can

see the beacon on the charger from about 3 to 4 feet away (this

is adjustable) and will drive to the charger when done sweeping

for the day. The charger contacts contains 15vdc at 1 amp and

a small charging board on the robot limits the charging on the

gel cell. |

This is where the

primary movement and intelligence is located. The base consists

of a two deck lexan construction, driven by two dc motors under

the base level.Also on the base level is the 12v gel cell battery,

microcontroller PCB, and touch sensors (bumpers). The top deck

carries the LCD display and the IR docking fine guidance sensor

bubble. The robots primary circuit board is our first home designed

printed circuit board, and is designed to be a universal robot

board as well complete with motor drivers and sub processors.

Sweeper Section:

|

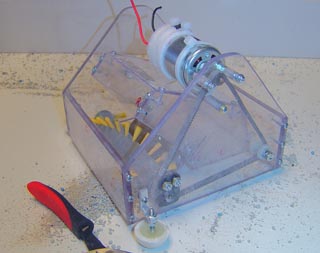

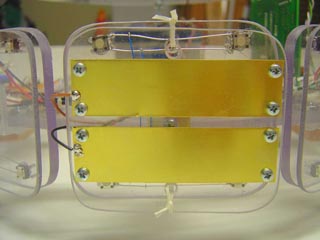

I

actually built this section first, because I wasn’t sure

how big it was going to be to do the job. Also constructed of

heavy lexan, this motorized brush section has a small dust tray

that can be dumped by releasing a magnetic door. A small circuit

board on the side carries both the 4v NMh batteries for independently

running the motor, and a buffered relay for simplified on/off

operation with the microcontroller on the main robot. Since I

am running the motor at half the voltage, it is relatively quiet

and needs a smaller battery pack. It will run up to 30 minutes

on an overnight charge if needed. |

The Docking Station:

|

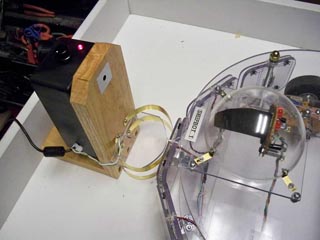

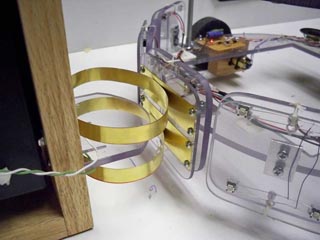

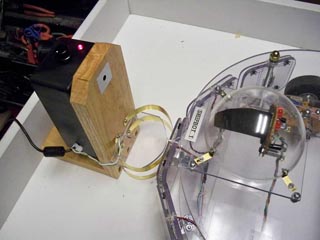

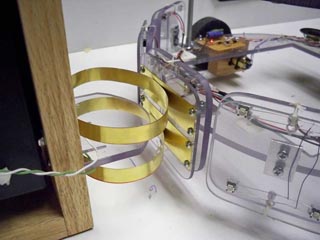

The

docking technology in this base was used from the best performing

design on the Picbot 5 project – “Docking Logic”.

Two brass hoops with a lexan separator are connected to a 15v

1A commercial power supply plugged into the wall outlet. This

will trickle charge the batteries when the robot is docked. The

power supply also operates the internal circuit board which consists

of a 38.5 KHz oscillator connected to the IR beacon LED. This

projects a narrow beam over three feet to allow the robot to

home in on the charging base. |

New Technologies

While the artificial

intelligence of this robot was heavily based on the techniques

developed in the PICbot series, several new technologies were

used for the first time on SweepBot. Here is a list detailing

these developments:

|

-

New impact bumper design – Using four touch contact type

micro switches sandwiched between two lexan plates was a new

and very reliable concept that was plenty sensitive and had great

flexibility in the morphology. |

|

-

New universal robot PCB – For the first time, a PCB was

designed in Express PCB design software, and several boards were

made. The board is intended to be universal, containing a large

16F874a processor several Texas instruments motor driver chips,

and two additional slave PIC 8 pin processors for servo control.

About half the board was filled here, only what was used in this

design. |

|

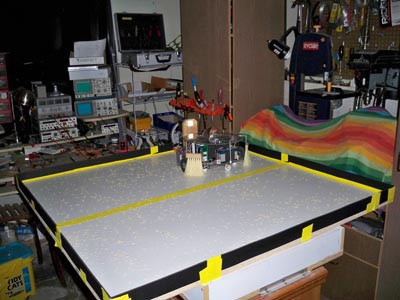

-

New larger robot test arena – The 14 inch size of Sweepbot

made it essential that the testing arena had to be larger. Two

white fiber board sheets combine to make a 48 inch square arena,

with three inch sides all around. In the future, this larger

size will make working with smaller robots seem like a whole

new huge universe! |

|

-

New docking contact design – The dual hoop design used here

was developed in the PICbot 5 project to be the most flexible

and reliable contact arrangement for robot docking and charging.

The contacts can compress about a half an inch to accommodate

the incoming robot which has dual plates mounted on the center

bumper to mate up with the hoops. It works very well in this

larger robot and Is fully scalable for future bots as well. |

System Operation:

The robot is programmed

with PIC Basic to run a “Finite State Machine” (FSM)

type of program, which provides the framework for the artificial

intelligence of the system. There are many caveats and error

conditions that can occur in a robot that is designed for full

time 24 hour a day operation! It took me the better part of six

months to craft the software to run the robot autonomously. The

basic operation of the Sweepbot is to awaken on the charger at

the first light of day. Next, after it confirms the sun is really

rising, and its getting brighter for a half hour or so, it undocks

from the charging base, and starts the sweep mode. The robot

moves about the room, using the bumpers to avoid walls and obstacles.

The AI for this was fully developed in the PICbot I program.

The power is applied to the sweeper at this time. After running

for about 10 minutes, the robot starts looking for its charger

and turns off the sweeper. When it finds the charger, it docks

with the charger which is located in a tight space between the

bathtub and toilet. It then confirms the presence of a charging

voltage, then shuts down and waits the rest of the day for the

onset of night. Once night is found when its getting dark after

sunset, it changes modes and searches again for the sunrise.

Then it will live its life again, over and over, day after day

keeping the floor cleared of bits of cat litter.

Testing and Evaluation:

Months of extensive

testing lasting sometimes for weeks on end were performed on

this robot while it was in four foot square “robot arena”.

There, every condition conceivable that it might encounter in

real life was simulated and programmed for. Uncooked rice was

used for faux cat litter for simplified testing of cleaning action,

and the development of the docking, and charging systems. Once

the robot performed a given period of time with any new changes,

we would move on to the next phase. Then there would be few surprises

when the robot was moved to its final cleaning destination upstairs.

Final Summary

This will be a

long term on going project. While I don’t see too many issues

with the carrier robot, how long the sweeper section will hold

up remains to be seen. Because it is modular, replacing the sweep

section with a new design is relatively straight forward. In

six months, Ill post an update here – stay tuned!

Photo Gallery

| My

inspriration, when I started this project 1 year & 4 months

ago, I saw this parking lot sweeper behind the circle K in town.

It works by pushing it and the back wheels drive the brush to

push the trash FORWARDS into the catch bin via a rubber ramp.

The rear wheel also drives a side brush to sweep stuff in the

curbs in front of the sweeper intake. The robots side brushes

do this very same task. |

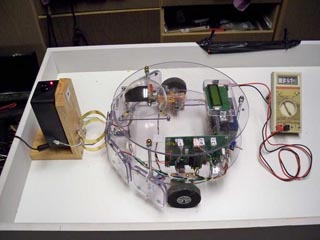

| Docked

on a rice sweeping test run. The side brushes can be seen well

here, and were cut with a bandsaw from a plasterers spreading

brush. It is one row of six that were on the brush. |

| Bottom

sweeper side view. The rotating brush pushes the dirt forward

up the polycarbonate ramp into the catch bin. Note the three

white round slides the sweeper runs on. |

| Rear

veiw showing the battery and position of the side brushes. |

| The

robots front bumper has two brass plates for connecting to the

charger. The robot drives up to the flexible hoops, connects

by confirming the presence of a voltage, then stops to charge.

The hoops can be docked with from a wide variety of angles. |

| Here

is the front central bumper of the robot showing the two brass

plates for charging. |

| The

robot homes in on the IR beacon on the charging base with this

vane type two sensor detector, which contains two PN4602 IR prox

sensors. Ive enclosed it in a plastic bubble to protect it. |

|

HOME