|

In this chapter

we will discuss the optical sensing techniques that will be integrated

into the robot itself, to enable it to locate and successfully

dock with the charger beacon. There are two steps involved with

this process. First, the robot must become aware that it is within

range of the charger beacon with a non directional Omni type

sensor that will detect the beacon no matter which direction

it is relative to the robot. This is called "Proximity Detection".

Once the robot has determined it is near the charger, a less

sensitive narrow angle sensor allows it to home in on the beacon

and direct it to the charging base. This is called the "

Directional Sensor". Here we will cover both topics, and

give you a sense of the approaches that are commonly used to

get our bot to its base. In these diagrams, sensors are usually

color coded red, as is the source IR beams.

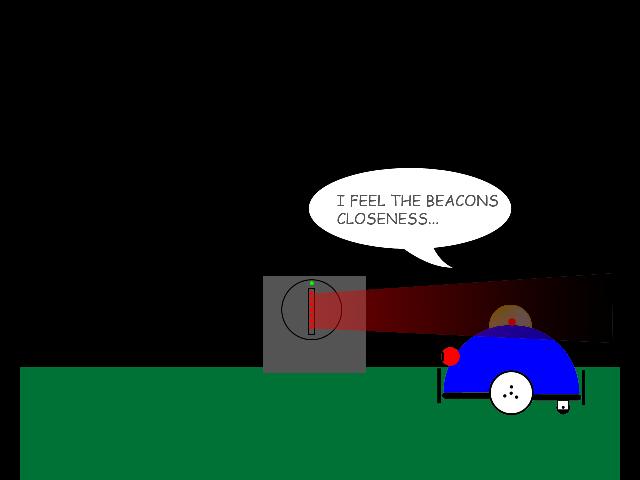

Proximity Detection

| A

very simplistic approach to proximity detection is to enclose

a sensitive IR detector inside a translucent dome. When the surface

of the dome is struck with infrared modulated light, the sensor

will see the domes underside light up and a crude detection is

accomplished. While fairly low in sensitivity, if one uses a

Panasonic PN4602 integrated sensor, the range can be six feet

or more in a normal room brightness. |

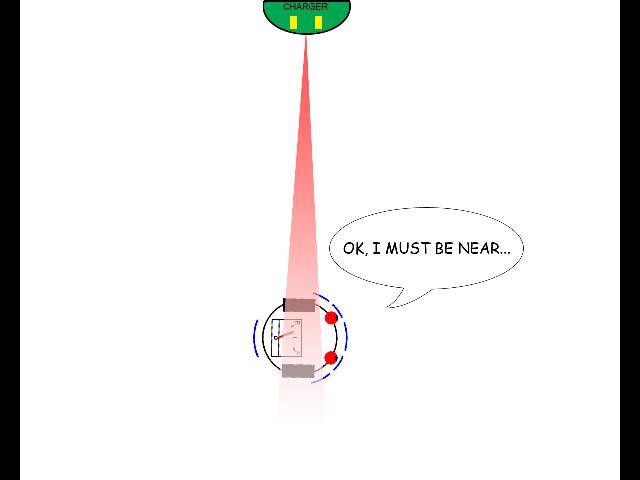

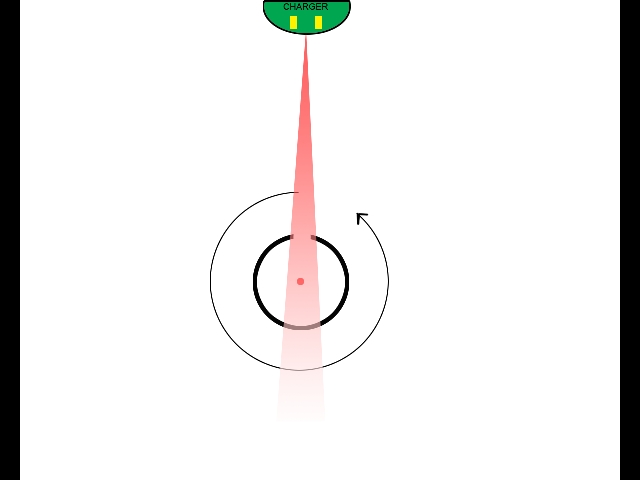

| An

overhead view of how this works is seen here. The beam will sweep

over the robots central detector as the robot moves forward only

when it is within the narrow confines of the beam. The robot

would then immediately stop, and start its routine for determining

the beams point of origin. |  |

| With

a centrally located multi-beam array on the beacon, the robots

chances for detecting its proximity to the charger are greatly

increased. Such an extreme approach is suitable for office or

factory environments, however the single beam is more suitable

for a home environment. |

Directional Sensing

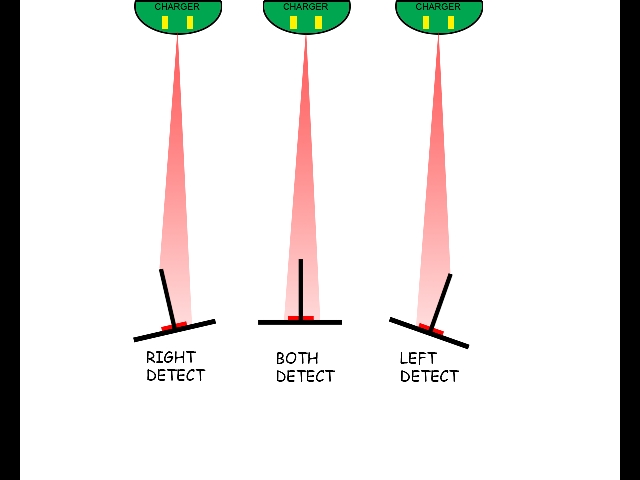

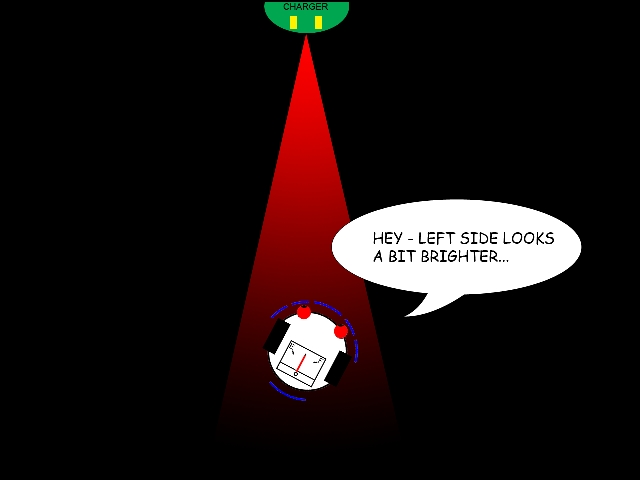

| This

is how the basic analog and digital vane sensors work. When the

vane points to the left of the beam, the right side is in the

light and the left side is in the shadow of the vane and sees

no light. By rotating the vane back and forth by rocking the

body of the robot or moving the sensor on a servo motor, we can

determine when the vane is directly aiming at the source when

both sensors just see light at the same time. In the case of

an analog system, cadmium sulfide photo cells can give a linear

voltage reading which indicates the source direction by comparing

the two output voltages. For a digital sensor such as the PN4602,

when the vane is exactly pointed at the source, both will have

an output. Proper filtering of the digital outputs is ESSENTIAL

for giving the microcontroller a clean signal. More on this later. |

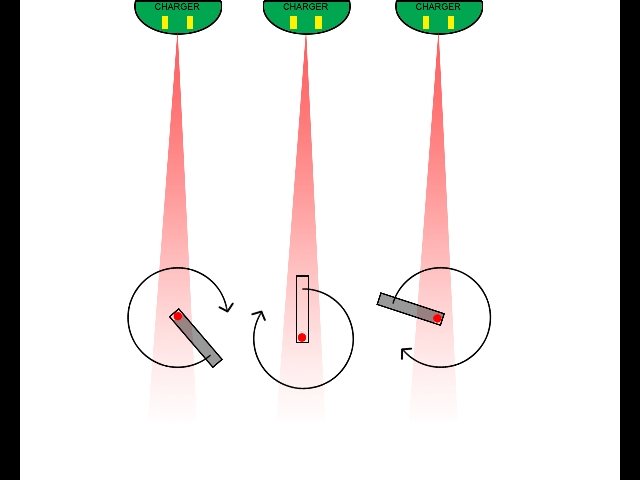

| Another

type of directional sensor used is the tube type. Here, a single

photocell is mounted at the bottom of a black tube. Only when

the tube is aimed directly at the source will there be an output.

The robot then rotates 360 degrees slowly and when the beam is

detected stops rotation. It then drives forward until it looses

the beam, then does its search all over again. This simplistic

approach can work fairly well, but the robot uses up a lot of

energy spinning every few feet to get to the charger! |  |

| A

rotating cylinder with a single photocell in the center or back

of the tube opposite of the slit can also be used to locate the

beacon. The idea is either the entire robot or just the cylinder

rotate, and when the slit in the side of the cylinder is aimed

exactly at the source, the photocell will become active. I rather

like this approach because the cylinder can be easily turned

by a servo, and the slit can be so narrow as to get directional

accuracy needed for a precise navigation to the charger. |

| An

example of a four way vane sensor in action. This was one of

our experiments with the PicBot5 and provided first, an crude

direction for the robot to turn, and second the vanes can be

used with two of the sensors to home right in on the robot. Later

we will have lots of images and some movies of this technique

in action. |  |

| With

an analog approach, and two IR phototransistors, we can simply

measure or compare the voltages from two sensors mounted about

where the eyes are in the graphic on the right. You can either

use a compartor to do the comparison and put out a digital signal

to the processor or send both analog voltages directly to the

analog in ports on the micro. |  |

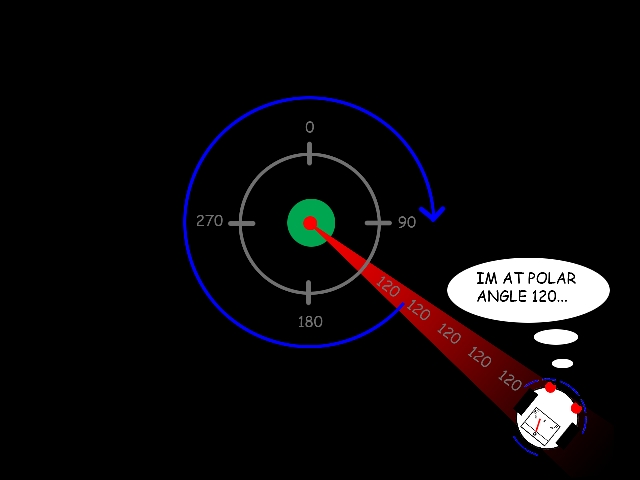

| A

very cool approach to beacon location is to rotate the IR beam

on the charger, and encode its rotation angle in the data stream

on the IR beam. The robot then knows its polar angle from the

charger and perhaps using sonar can get the radius to the charger

to get its exact position in the room. |

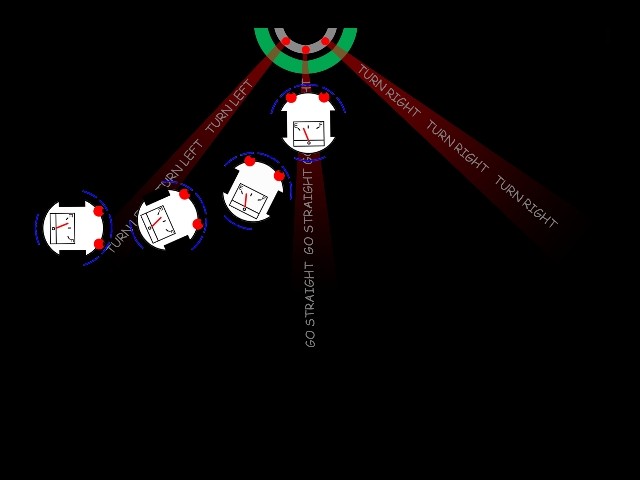

| The

"Roomba" docking technique is to encode in the beam

what the robot should do if it encounters the beam. So the robot

will drive along, into one of the side beams and start turning

toward the charger as it is instructed to do so. Such a system

must be perhaps in a hall way to limit the robot so it does not

cross the center beam first. |  |

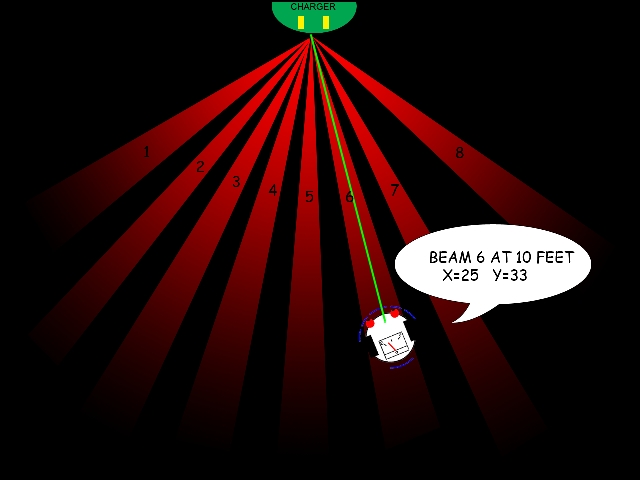

| Another

thought at encoding the beams with data, if we simply number

the beacon beams which are active all of the time, we can get

directional information to the charger. This allows us to COMBINE

a charger beacon with a complete navigation system in a small

room or office area in one unit. |

|

HOME