|

At some point in this article,

we have to support the theoretical discussions with actual results

from the laboratory. We spent many hundreds of hours on designing

and performing docking experiments with the PICbot 5 unit, which

was typically rebuilt every time down to the bare chassis for

specific experiments. Were going to take each lab example one

at a time here, and go into great depth on the techniques and

hardware used to make a real world robot actively seek and dock

successfully with its battery charger.

About the Robot.

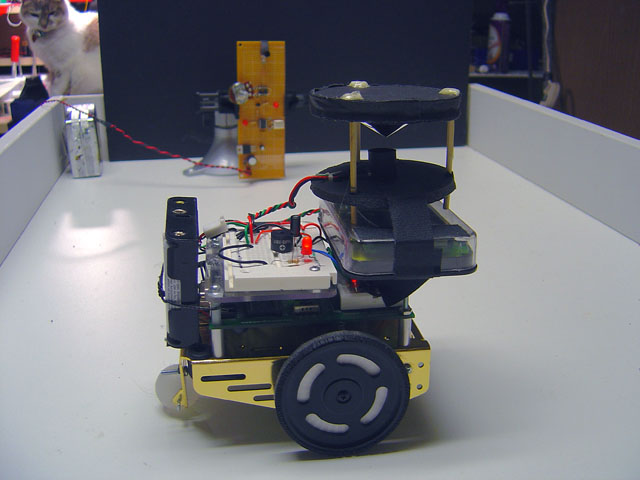

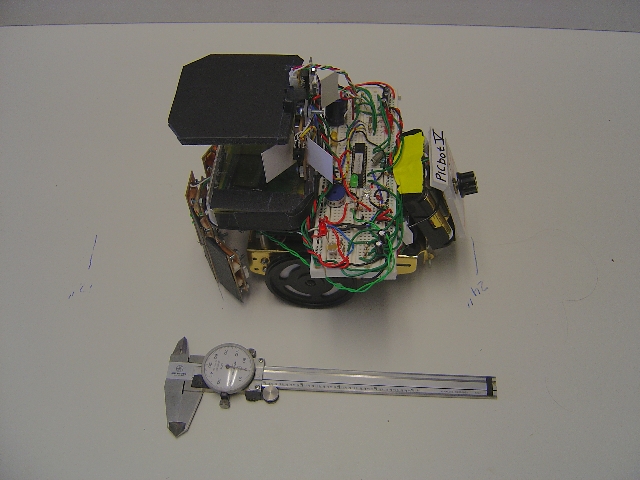

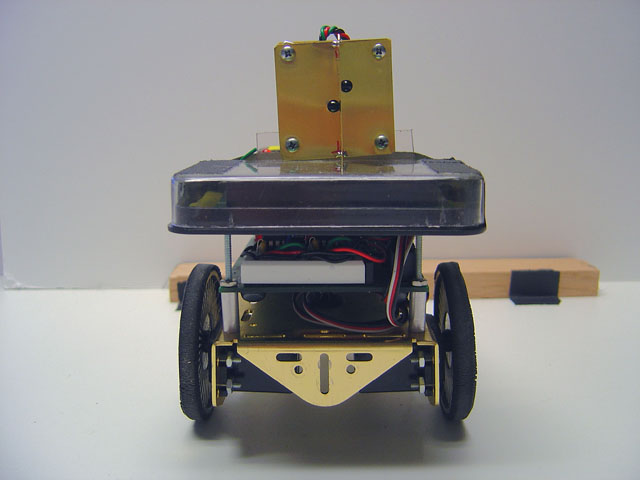

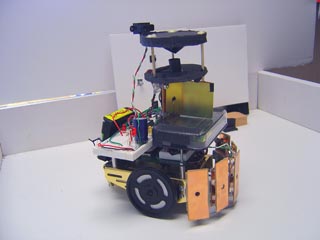

PICbot 5, which

is the fifth in a long series of PICbot articles is essentially

a bare stripped Boe Bot chassis, with serially driven home brew

servo driver PIC processors that are commanded by the test processor.

In most cases, the processor was either a 16F73 or 16F876A Microchip

PIC, with a total of 28 pins. These controlled two 12F629 home

brew RS232 servo drivers and completed the intelligence section

of the robot. All of our programming was done in PICbasic Pro.

For power, 8 AAA NiMH batteries were used to power both the motors

and experiments. Two push in type proto boards rode on the top

of the robot for quick changes to the hardware, and we also put

in a Scott Edwards serial LCD for communication from the robot.

We will break down

this rather large section into Detector testing, Proximity, precision

alignment, and docking contacts. We'll also throw in any schematics

or drawings as needed. Finally, we will summarize our Lab results

and suggest where to head from here.

Section 1: IR Range

Testing

Testing the PNA4602

Sensor

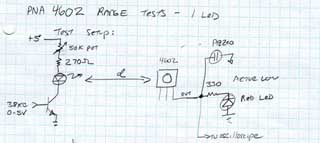

| First,

lets go over the basic beacon circuit we are using. A 38.5 KHz

source coming from a precision function generator drives the

NPN transistor for modulating the IR LED at the correct rate.

In our test circuit, I've also added a 50k pot for brightness

adjustment for range testing. This signal is received by the

Panasonic PNA4602, which drives both a standard red LED and a

Pizzeo speaker to hear the switching noise. |

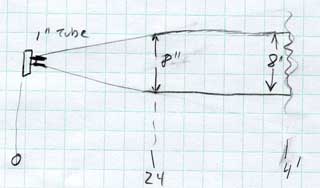

| A

suitable narrow beam pattern was obtained by installing a 1/4"

diameter tube that was one inch long over the IR emitter. A beam

spanning 8 inches wide at its fullest resulted in this way, as

detected by the PNA sensor. |

Click for a larger view

Click for a larger view

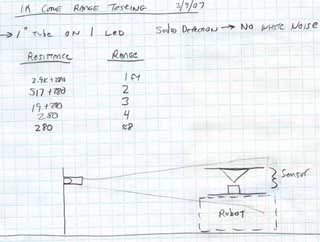

| Our

notes on range testing. In a nutshell, for a four foot range,

a 1.5k resistor was used, When the power was high, such as when

we used a 270 ohm, the reflections off of the inside edges of

the tube and distant walls made the measurements very difficult.

Keep your power low, and limit your range to less than 10 feet. |

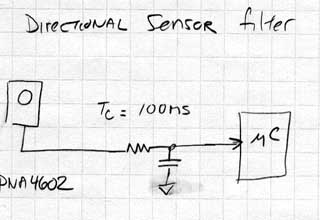

| A

VERY crucial part of using the PNA sensors is to filter their

digital output with a low pass filter to control the rapid transitions

that occur at the switching points. Your robot will encounter

many instances where the beam is only partially detected such

as in vane homing. The slamming square waves that result will

totally confuse the processors. So we did numerous experiments

to determine how much filtering was needed and yet still give

good overall response. |

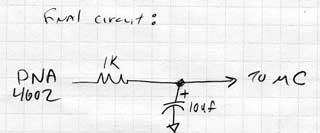

| The

resulting values were 10 uF for heavy filtration, and 1 uF for

most applications. This is what we used for the testing. |

|

Range Testing.

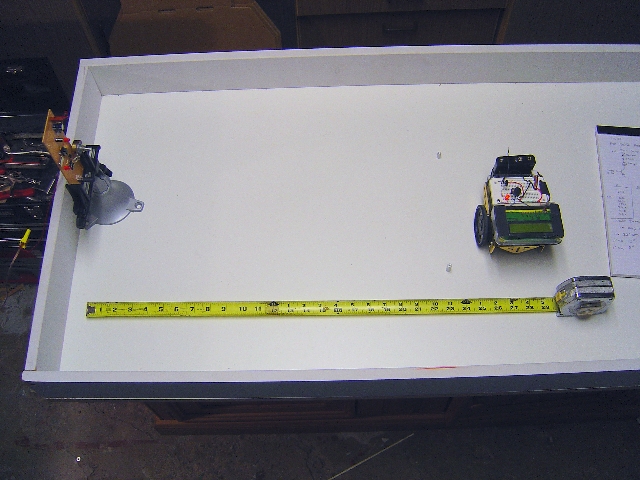

The robot was moved

back and forth to determine the range of the PNA sensors with

the beacon set for different drive levels. We were able to adjust

the detection limit from about 6 inches out to over 10 feet,

well past the ends of the Robot Arena.

|

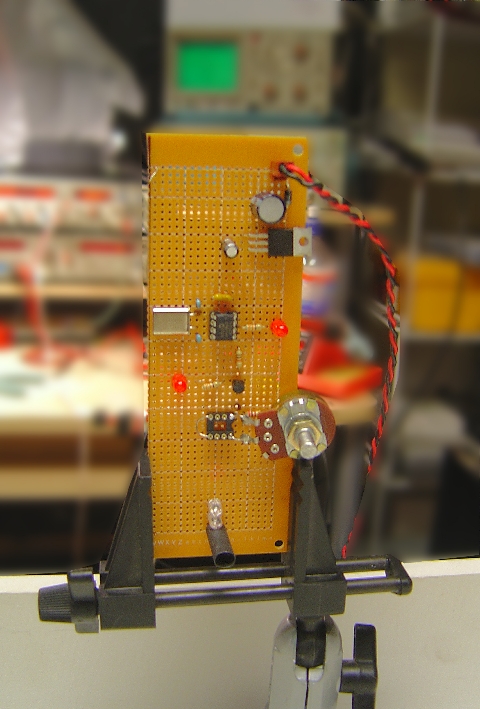

| The

bare Beacon with the IR LED at the bottom in a black tube. The

range pot is below center, and 5v regulator at top. We used a

small PIC for the 38.5k source as in the schematic below. |

Click for a larger view

Click for a larger view

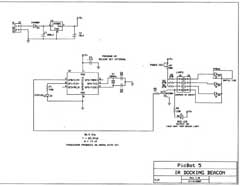

| Schematic

of the beacon. A 12F629 PIC processor was programmed to simply

go high and low at the correct rate to generate the square wave

form to drive the IR LED. This was accurately measured and tweaked

with a frequency counter as well. A 10mhz xtal was used for stability. |

Section 2: Proximity

Detectors

Building an Omni

Cone Sensor

Warning:

Heavy Math Ahead!

For those of you

that are versed in geometry and trig, we will share our notes

with you on the design process for designing a very accurate

omni cone. For those of you not interested in the math, we provide

the dimensions at the end in the drawings for you to copy and

make a cone like ours.

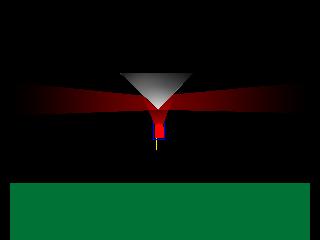

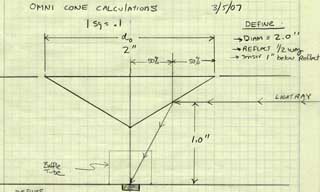

| Basic

concept of an omni cone beacon, or IR receiver assembly. Light

from the modulated IR LED shines upward to the cone, and is diverted

exactly at right angles to the surface to reach out across the

room in all directions. Similarly, if the LED here is replaced

with a PNA4602 sensor, it can become a very wide angle proximity

detector on the robot as well. |

Click for a larger view

Click for a larger view

| Lets

start with a basic definition of our side view of the cone, with

a few dimensions we wish for the final design. |

Click for a larger view

Click for a larger view

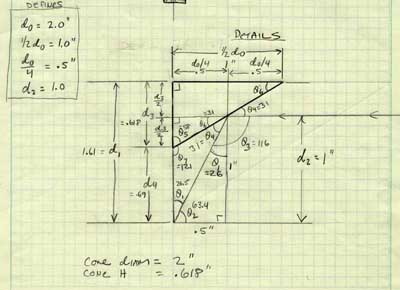

| Breaking

it into a geometrical concept, I've labeled some of the angles

and dimensions we will be calculating. Note the "Defines"

in the upper left, that is our starting points. |

Click for a larger view

Click for a larger view

| Next

we calculate each parameter in the geometrical concept. |

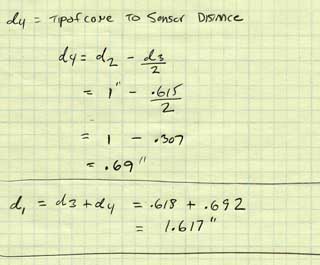

| d4

allows us to see that our sensor to cone tip is about .7" |

Click for a larger view

Click for a larger view

| And

finally, with all the numbers, we actually have to MAKE the cone.

I spent quite a few hours pondering this one! Here is my mathematical

technique, you make a disk out of the reflective material (discussed

later) and cut a pie shaped wedge out of it. The cone is then

folded to the cut outs to make the 3D shape. Pretty cool, ay? |

Click for a larger view

Click for a larger view

|

Preliminary

cone tests

Range was considerably

reduced when working with a cone rather than directly with PNA

sensor looking right at the beacon. About half the range resulted,

with the center of the cone the same height as the beacon LED.

|

Making the cone,

step by step

Here is a photo

pictorial of how we made our cones for testing. The material

was a very highly reflective mylar coated poster board material

obtained at a craft store for about $30 for a big 2 x 3 foot

sheet. Many years supply for making cones!

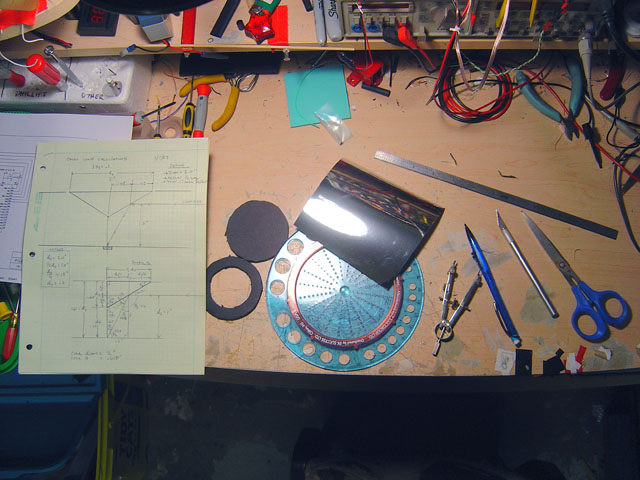

| Laying

out all the tools for the task. A precision protractor and compass

are a must, and sharp razor cutters for trimming the exact angles

as well. |

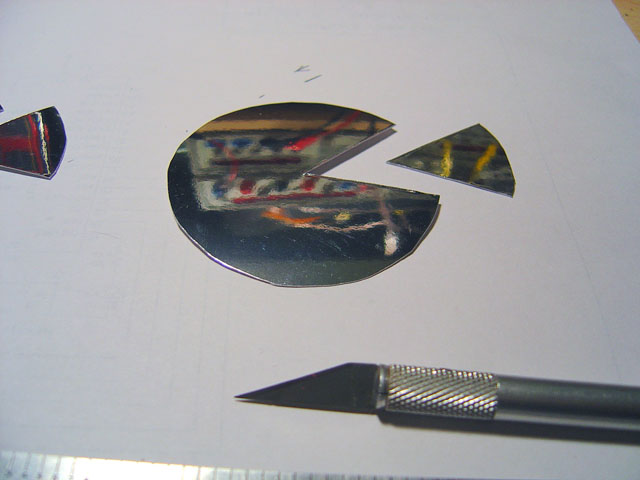

| The

disk was cut out of the mylar board, and the angle of the pie

shaped cut out drawn in. Using the blade, we cut out the wedge

from the disk. |  |

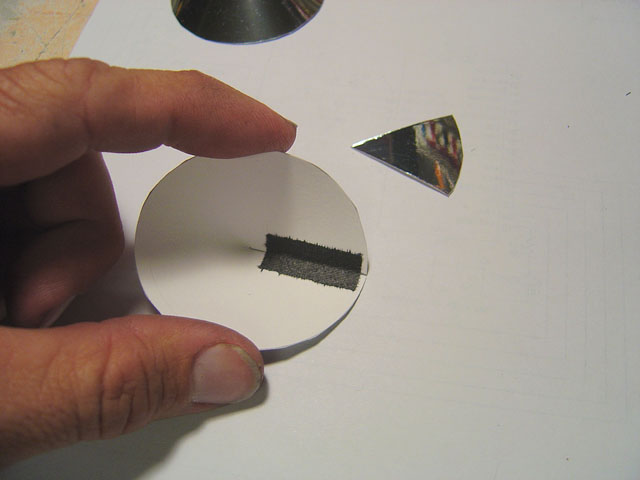

| From

the rear some cloth tape sealed the seam to make the 3D cone

a reality. |

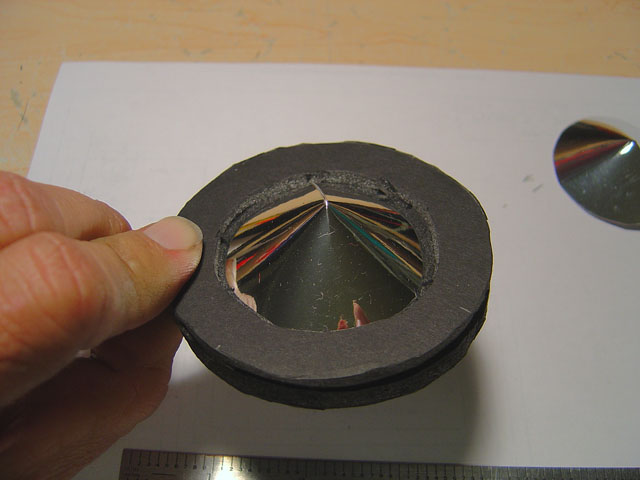

| We

then dropped the cone into a base made from foam board that was

the same diameter as the cones base. This holds it round and

symmetrical. |  |

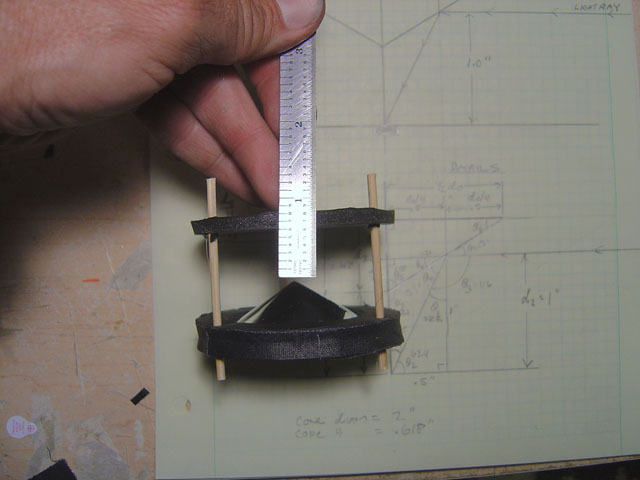

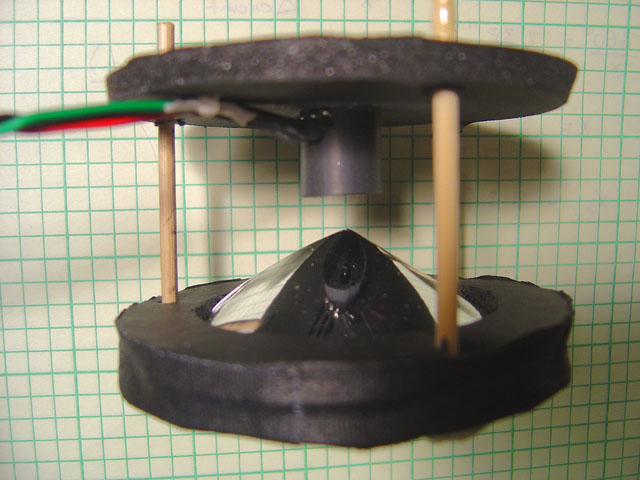

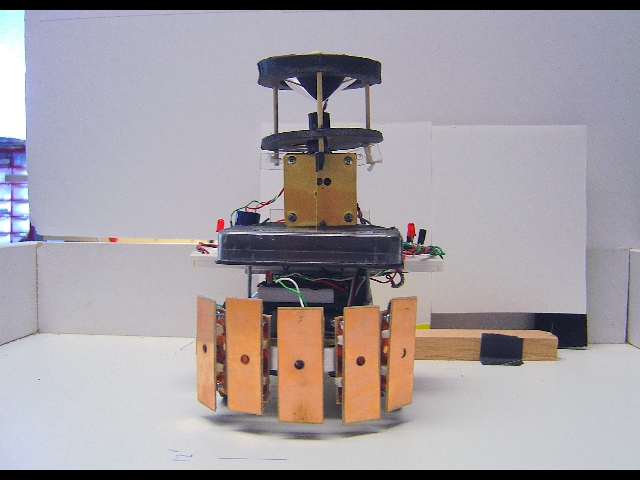

| Three

struts were added around the cone, and the top sensor disk was

set for the .7" spacing + the thickness of the sensor. |

Testing the Omni

Cone Prox Sensor

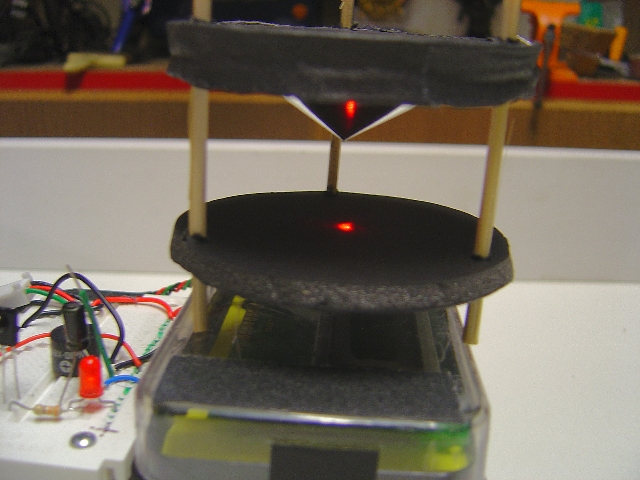

| The

omni cone mirror assembly mounted on the top of the PICbot V

platform. A laser was mounted in a vice and pointed exactly level

at the center of the cone. The reflection should hit exactly

in the center under the cones tip if we did our math right. |

| Mathematical

triumph! The laser strikes the point under the cone no matter

how the cone is rotated. In other words, you can spin the

robot and the beam always hits the exact center of the bottom

disk. |  |

| Shining

a bright light on the cone, we can see the sensor inside the

short black baffle tube from any angle. No matter how you rotate

the cone assembly, you will always see the reflection of the

sensor like this! |  |

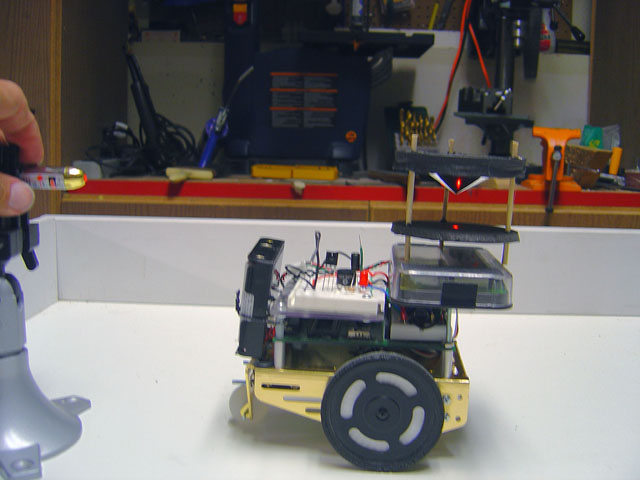

| PICbot

V ready for omni cone proximity testing in the robot arena in

our lab. |

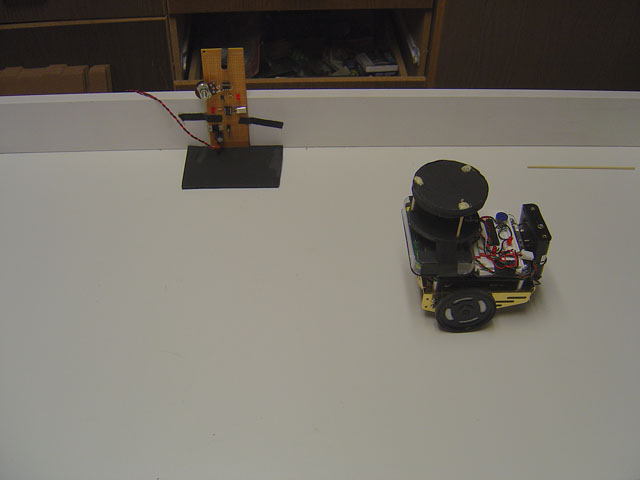

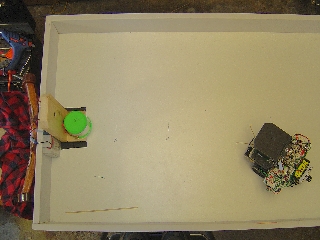

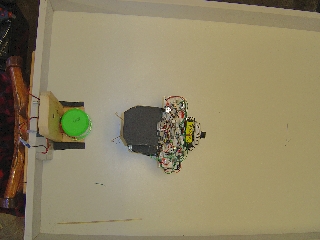

| Range

and angular detection testing. The robot is programmed to go

straight until it detects a signal in the omni cone proximity

sensor, then stops. We can then measure the response and acceptance

thresholds for the device. |  |

Click for a larger view

Click for a larger view

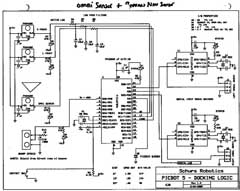

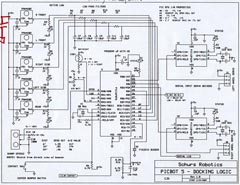

| PICbot

V schematic diagram. A 16F876a main processor drives two smaller

servo driver processors we designed to operate with RS232 data,

and take the data from all the sensors. |

The 4 way Prox

Sensor Array

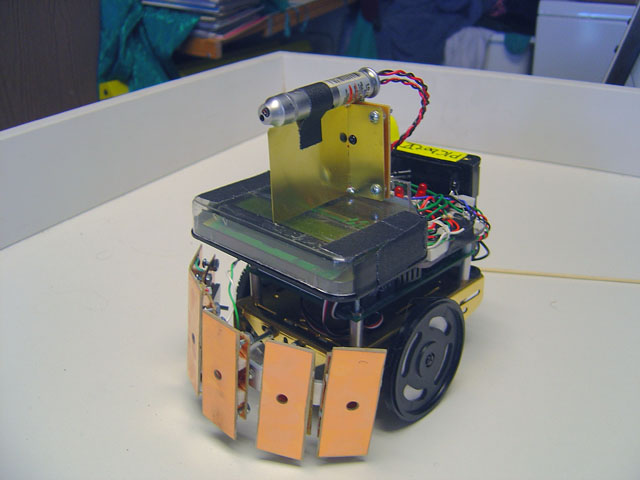

Another type of

proximity sensor we tested was a 4 way vane type. Here, four

PNA detectors were mounted at the vertecies of an X shaped arrangement.

The effect was to have one in the rear and front, and one on

each side. In this way, we can not only tell in a 360 degree

range there is a nearby beacon, but approximately on which side

of the robot.

|

Vane

sensors mounted on the robot. You can see them as small black

PNA sensors mounted in between the white cards we used as vanes.

So here, the left side is covered by one sensor, with nearly

no overlap with the front and rear sensors giving us some indication

of the direction of the beacon. |

Click for a larger view

Click for a larger view

|

The

complete schematic of PICbot V with the vane proximity sensors. |

Section 3: Precision

Alignment Sensors

Building a Vane

Type sensor array

In this section,

we will go step by step on how to construct a very accurate positional

vane type sensor. You know from the theoretical diagrams we showed

you earlier how they work, and now lets put that design to a

practical application. Remember, the vane sensor is used to actually

point the robot and guide it right to the beacon.

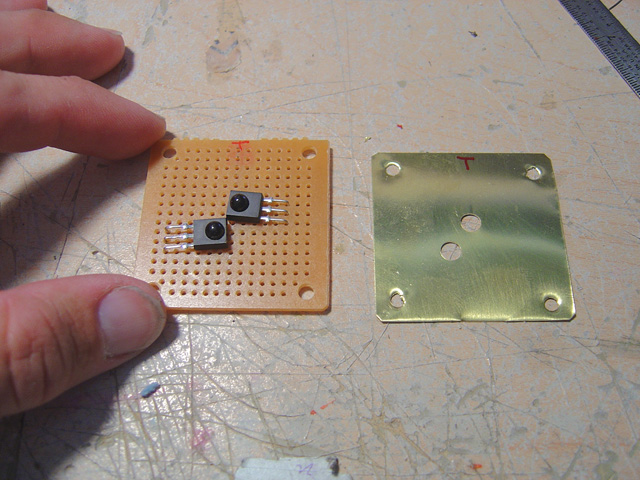

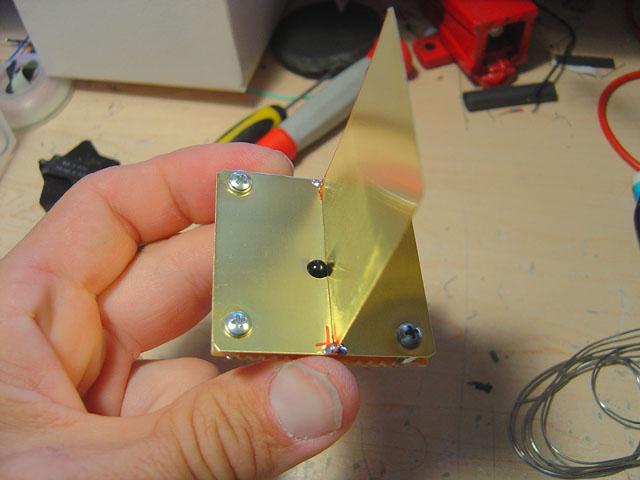

| Two

PNA sensors are mounted like this staggered to get the sensory

chips as close as possible on the horizontal plane. A mask, made

from brass here is carefully drilled to match the lenses. |

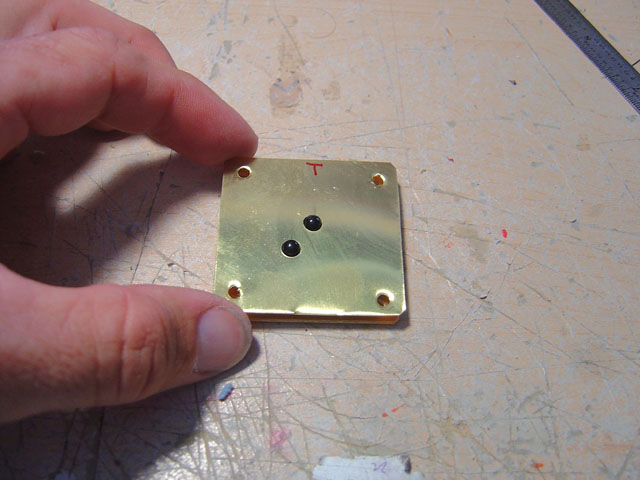

| When

the brass mask is over the sensors, only the lenses protrude. |  |

| Laying

a metal scale between the lenses shows how close they are to

the vane. This will give us the maximum resolution in pointing

at the beacon. |

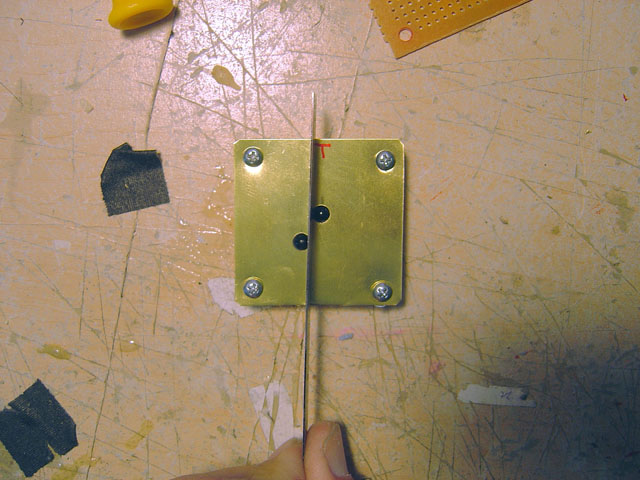

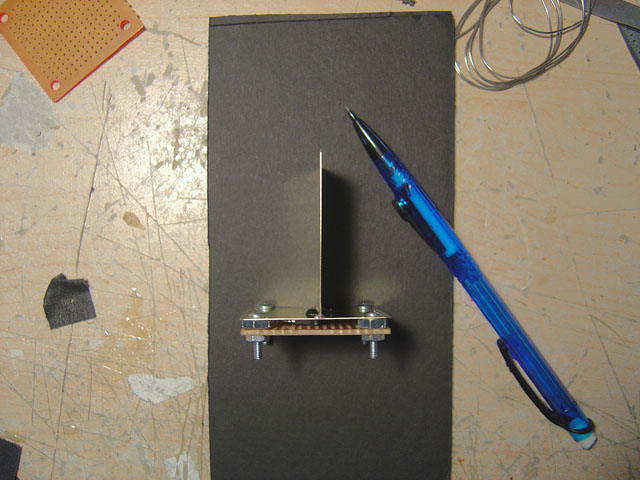

| The

actual vane, here about 2 inches long is soldered onto the mask,

and at an angle of exactly 90 degrees. Now you can only see one

sensor at a time. |  |

| From

the top, we can see the perfect perpendicular angle of the vane

relative to the base. I used a square when soldering to do this. |

Testing the Vane

Sensor Array

| Mounted

on the PICbot, and wired into the processor, we can program the

robot to report the position of the beacon by merely examining

the sides the sensors are active. And once again - make CERTAIN

to always include the RC filter in the outputs of the PNA sensors

for crisp clean outputs. Here both sensors are active because

the beacon is exactly straight ahead. |

| The

left sensor is active, and right shadowed. So the robot reports

the beacon is on the left. |  |

| Now

the right is active, and left shadowed. |

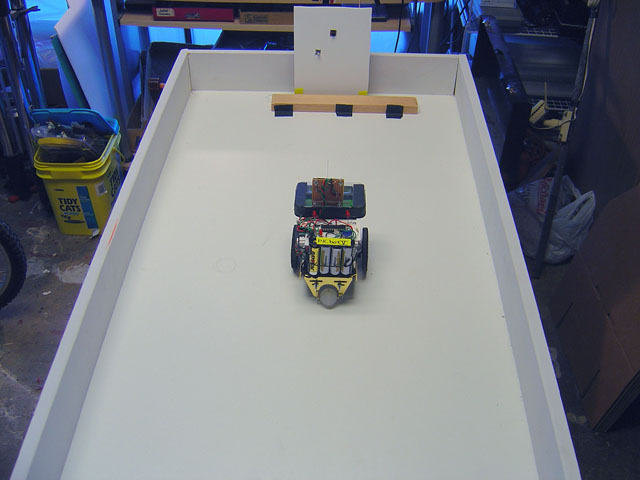

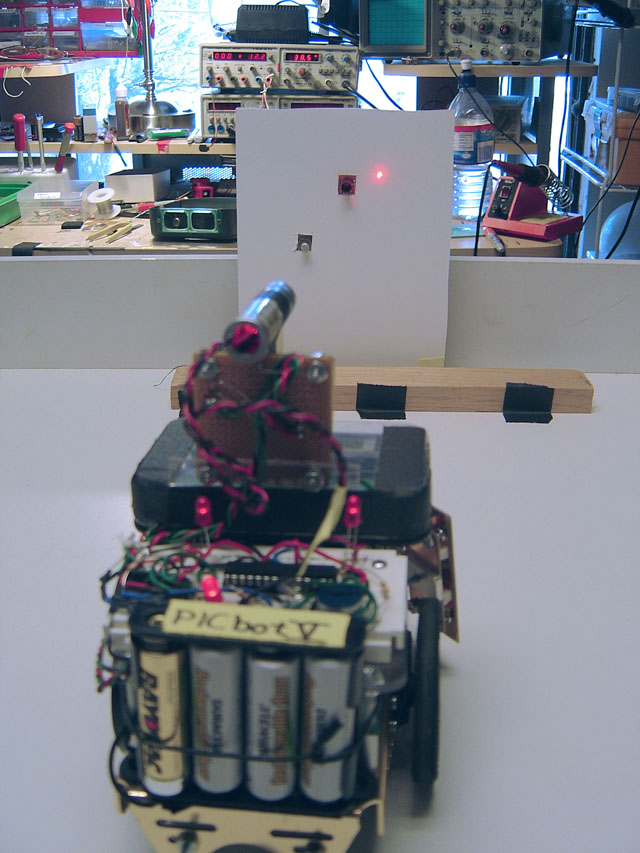

| For

our precision aiming tests, the setup included the beacon mounted

behind a white board with the LED tube and pot sticking out for

brightness adjustments. A wooden stop prevents the robot from

ramming the board. |  |

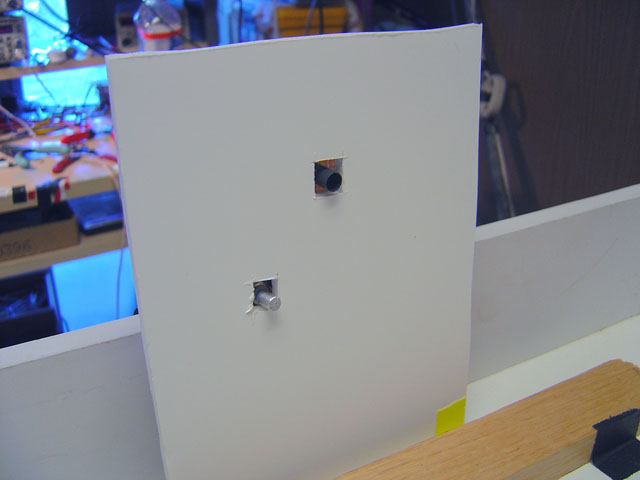

| The

test beacon close up. |

| From

the front, the central vane is nearly invisible, and we can see

the two sensors ONLY when the vane is aiming exactly at you. |  |

| By

attaching a laser to the top of the vane, we can see where the

robot is aiming when it homes in, to determine its wobble and

pointing accuracy. |

| The

laser in action. Here, the robot moves towards the beacon defining

a somewhat jerky "S" shaped path. The beam will sweep

across the beacon but is centered dead on target. This was instrumental

in allowing us to determine how the vane length affected accuracy. |  |

| The

robot stops at this point in the test on the bumper stop, aiming

exactly at the beacon. The bumper impact stops the wheels during

each test. Accuracy was determined by the spread of contact points

along the wooden beam. |

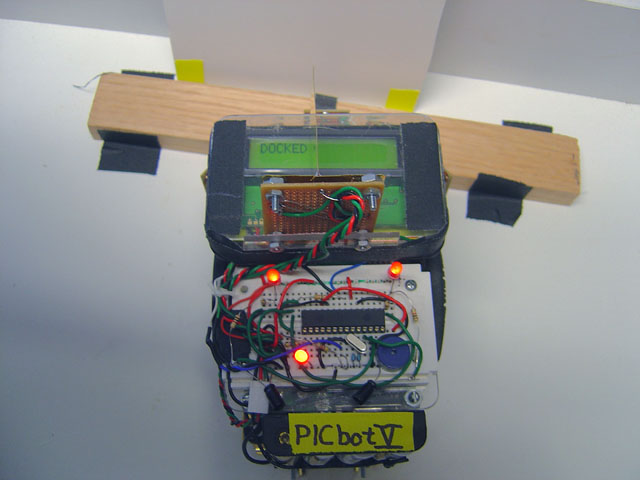

Docking sequence

three part pictorial.

To determine the

docking accuracy of each sensor/beacon combination, the robot

was programed to drive to the beacon, and stop when its front

bumper touched the wood slat. The position of impact was marked

and another trial was performed. After many trials, the range

of contact points became well established.

|

Movie

1

PICbot V acquires

beacon with the precision detector, and drives to the test base

as seen above. This is a short movie.

|

Movie

2

A pretty cool short

movie, showing the robot homing in on the beacon with the laser

on its top pointing in the same direction as the vane in the

precision sensor. Watch the red dot on the target!

|

Combining the Sensory

Arrays

Proximity Cone

+ Precision Vane Sensor

| The

robot in its test configuration. On the very top is the Sharp

IR range detector to measure the distance to the beacon housing.

You'll recognize the Omni Cone sensor below it, sitting on the

vane type precision direction detector sensor. The LCD display

allows us to monitor what the robot is currently thinking, and

the last sensor array is the bumper ring you may recognize from

the PICbot II program. |

| Frontal

view showing head on - this is the view the beacon would see

if the robot were approaching. |

Docking sequence

from a movie showing the robot driving at an angle into the beam

in frame 1, Omni cone proximity detection and stopping in frame

2, Precision acquisition frame 3, the drive in frame 4, and finally

docking frame 5.

|

Movie

3

| The

movie of the above sequence, note also that the robot rotates

a full circle to look for the beacon after it stops initially

to get a lock on the beacon. Also very critical - the robot slows

down to half speed when it gets within about six inches of the

beacon. |

Section 4: Docking

Contacts

Docking with Dual

Hoops

Now were adding

some "REAL" electrical contacts to the lab tests. One

of the most successful contacts was the dual docking hoops. The

front of the robot has a modified bumper with a split copper

plate on the front to contact each hoop with the 12 volts of

charger voltage. You will now see when the robot docks successfully,

that I've put a brilliant white LED on the e robot to show it

has made electrical contact, seen well in the last frame here.

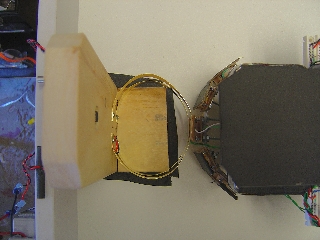

| The

test charging beacon consists of a base with the IR beacon at

the top, and dual spring loaded opposite polarity charging hoops

at the base. The hoops are made from brass strips about half

an inch wide and a foot long. |

| On

a direct drive in, when the robot touches the hoops, they compress

slightly making a perfect contact with both upper and lower bumper

plates. The acceptance angle is huge, and allows for success

in docking better than any system we tested. |

| Coming

in from the top, you can see the hoops still conform to the front

of the robot. |

| Any

angle within a 90 degree range will dock just fine. Making this

the best and most versatile system for docking contacts. |

|

Movie

4 | This movie shows the robot docking with

the dual hoops with its usual success. I've now added a potentiometer

to the back of the robot that allows me to dial in any battery

voltage level I want into the robots battery sense inputs. When

the robots battery is above 10v, the robot sits still and allows

what would be a higher level of priority programming to do its

task. When I turn the knob to less than 10v, the robot takes

off and docks. This is because now the priorities have changed,

and the prime task is to recharge. |

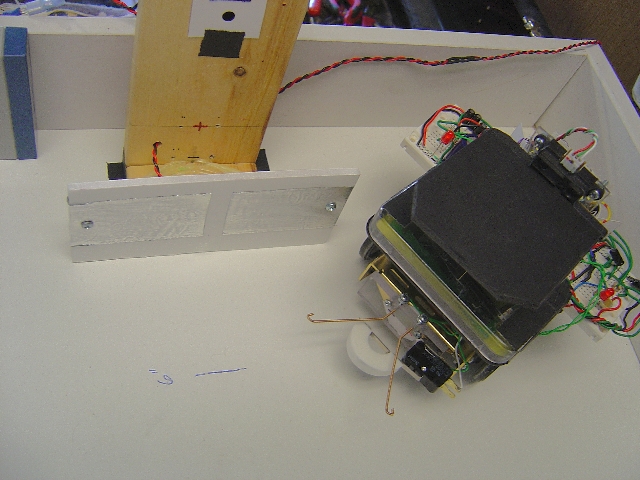

Docking with Flat

Charge Plates

For this method,

a flat panel with two foil plates with opposite polarity was

mounted on the charging base. The robot was then equipped with

two short whisker type contactors, and a bumper contact between

them for testing. Here are our results of this technique.

| The

flat plates on the charging base, and robot. Note that the omni

cone has been removed, since we are mainly concerned with the

actual docking performance. |

|

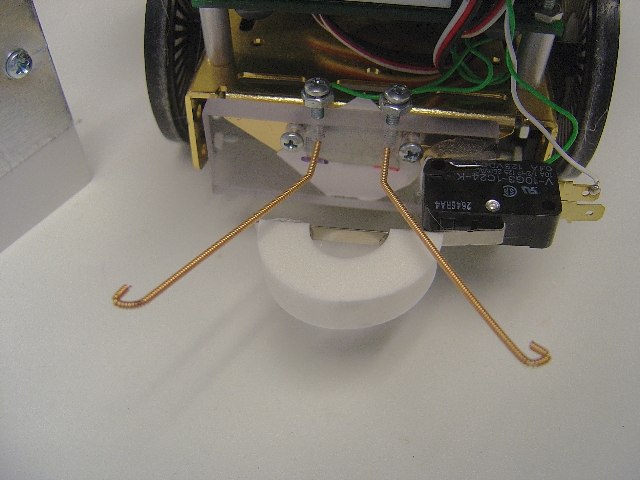

The front

of the robot has to brass wound guitar strings for contacts,

and a lever switch with a foam bumper between to tell the robot

when to stop should it not see any electrical voltage first.

|

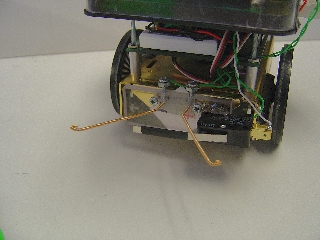

| From

above the plates, we can see as the robot heads in, the whiskers

will each touch their own plate. This works very well when straight

on, and becomes less effective at steepening angles. Limiting

the beacon angle to fairly narrow will take care of this for

the most part. The advantage of this system is fairly obvious

- extremely compact, and can be wall mounted anywhere. |

|

Movie

5 | This movie shows the robot acquiring the

beacon, and driving right in to the plates. Take a good look

at this movie - this is the easiest docking station we have made

yet and you may want to use this design. |

Docking with the

Whisker Cylinder

A variation is

to wrap the electrical contacts around a cylinder and connect

with brass whiskers.

| This

docking station shows the beacon at the top, and the cylinder

which was a spray can lid wrapped with the foil tape. Screws

on the sides allowed us to attach wires to make the electrical

connection. |

| For

this arrangement, the foam bumper was removed and replaced with

a rubber non conductive piece of tubing. |

|  |  | The

acceptance angle of this method is far less than the plates on

a flat surface because the robot must actually wrap the whiskers

around the cylinder to make contact. But it is easy to make,

and gave good results. |

|

Movie

6 | Docking with the cylinder. The robot drives

in, and very rapidly connects to the charger. It is helpful to

have the wheels slip a bit when it connects to make it seat well. |

Section 5: Final

Words

|

For

nearly ALL our docking experiments, this very carefully honed

Finite State Machine (FSM) was used. Study it carefully and you

will see that there are escape and failure contingencies to cover

nearly every situation. Making a diagram like this will enable

you to cover nearly all your bases when programming a successful

autonomous docking robot. |

Living and

working with a self charging Robot

From what we have

shown you here, you will now have a much better feel for the

possibilities and complexities of an autonomously recharging

robot. You will be opening a whole new dimension in home or office

robotics when you include this function in your creations. For

example, many people have named their Roomba floor cleaning robots

pet names, and when they finally fail, they will grieve for them

when they are gone. Your robot becomes an artificial life form

at this point it can actually sustain or "feed" itself.

We have run some of our robots for weeks on end in the house

during different projects, and after only a few days, they seem

somehow more alive as they go about their task. Our cats even

accepted P.A.A.M.I. as another animal, tried to pounce and play

with it as it roamed about.

Moving into the

Future

So where do we

go from here? With a fully autonomous self recharging robot at

hand we can start to program tasks into the machines that involve

long term goals. Examples include Daily floor sweeping, watering

the plants every two days, deliver the laundry basket to the

washer each week. And in the office, make the rounds each morning

to deliver mail, or documents. All of this is possible now, with

your self recharging robot!

|

Click for a larger view

Click for a larger view

Click for a larger view

Click for a larger view

HOME